Vibration Shakers & TESTing Software

Ensure Your Products Perform During Real World Environmental Stresses

Reproduce pre-defined test specifications on a SignalForce shaker, or go out in the field and create your own test specifications with a SignalCalc 900 Series Analyzer. Whatever your environmental testing requirements are – Data Physics has a turnkey system to complete the tasks at hand.

A Single Source Solution

Quality. Controlled.

We don’t put our name on third party goods. Data Physics engineers all of its products in-house.

Made in the USA and Europe

All shakers, amplifiers, controllers, and signal analyzers are engineered and manufactured in the USA, England, and France.

Experienced Support

Our application support team has an average of more than 15 years experience in the industry.

Shaker Testing Applications

Electrodynamic Shakers

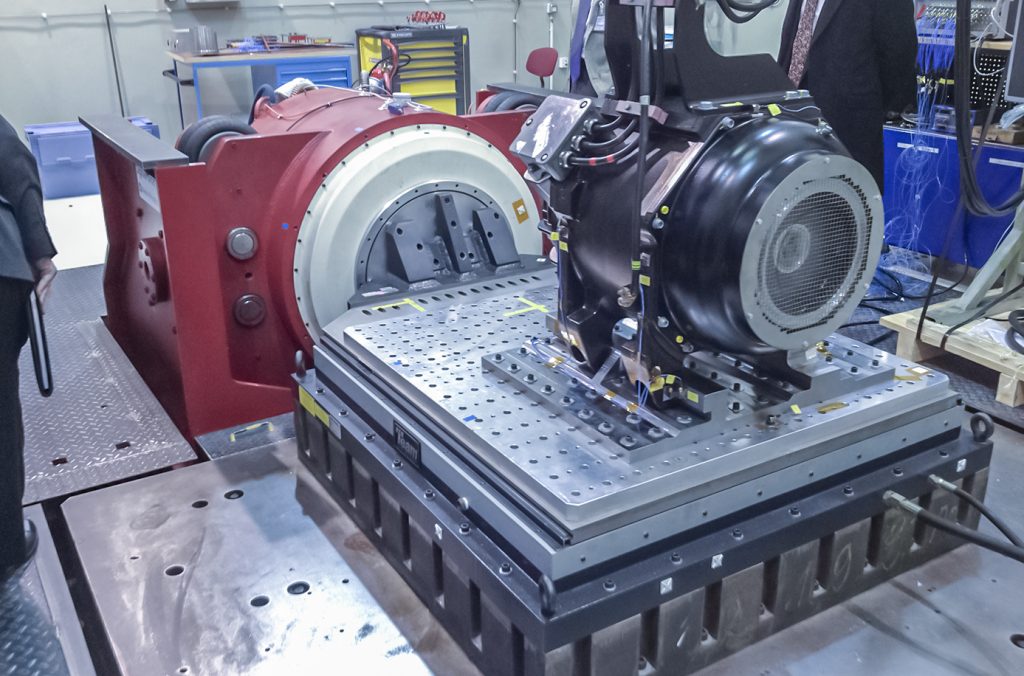

Data Physics SignalForce Electrodynamic Vibration Shakers provide the foundation for a broad range of comprehensive test systems, meeting both single and multi-axis testing requirements.

Amplifiers

Data Physics SignalForce Amplifiers combine high levels of efficiency with superior performance, while occupying little space and are suitable for driving shakers from all manufacturers.

Vibration Controllers

Powerful, easy to use vibration testing software and reliable Data Physics hardware lets you quickly create and run any vibration test profile.

Integration with Lab Equipment

Integrate your Data Physics shaker/controller with other lab equipment such as a thermal chamber or supervisory controller.

Signal Analysis

Measure vibration in the field with SignalCalc Analyzers, and seamlessly replay it on your shaker in the lab.