Automotive Vibration Testing

Shakers, Controllers, Amplifiers, Slip Tables, Head Expanders, and Accessories for Automotive Vibration Testing. Signal Analyzers for Vibration and Acoustic Measurements.

Data Physics provides a full range of products for automotive vibration and acoustic testing.

Shakers, Amplifiers, and Accessories

- Data Physics offers a wide range of shakers/amplifiers from 2lb to 50,000lb

- Standard and custom head expanders and slip tables to fit your test article size

- Up to 3″ Stroke in an electrodynamic shaker

- Test from <1Hz to >5kHz with the new IGBT amplifier

Digital Switching Amplifiers

Digital switching amplifiers are available from 1 kVA to 405 kVA and can be provided in a broad array of configurations, tailored to deliver the power necessary for more challenging testing requirements and automotive industry standards.

Linear Amplifiers

Our Linear Amplifiers are available from 30 VA to 1 kVA, and provide compact and efficient solutions for smaller test items with comparably lower-intensity test inputs. These amplifiers are well-suited for inertial and modal shaker applications.

Increase Your Shaker’s Performance with SignalForce IGBT Amplifiers

Designed with the Data Physics LE-series shakers in mind, the new LE-DSA15 IGBT amplifiers are based on the same reliable and robust architecture as the LE-DSA10 series units, which have a proven track record of continuous high output operation. The LE-DSA15 amplifiers are rated for 200 Vrms continuous operation which will allow for high velocity testing without the need for an output transformer – saving floor space.

When connected to a LE-DSA15K amplifier, the LE-2016-3″ shaker systems are capable of up to 170 in/sec (4.32 m/s) velocity shock at 11 mSec.

The Multi-Faceted 900 Series Vibration Controllers

Run any Pre-Defined Spec

Random (w/Kurtosis), Sine, Shock/SRS, Sine/Random-on-Random, Time Replication, and more.

Field Data Recording and Playback

Record field data with the portable Abacus 901, and replicate the vibration on your shaker with the same Abacus 901 unit functioning as the controller!

Integrate with Existing Lab Equipment

Signal our software to start/stop with analog or software messages – or control your other lab equipment with our software.

Automatic Data Archiving

Data and test profiles are automatically saved into a searchable test database.

Shared Test Database

Multiple test stands can share the same test database, and data can be reviewed and reported from anywhere on the network.

Use Your Vibration Controller as a Signal Analyzer

All 900 Series Hardware can function as a Vibration Controller, Data Recorder, or Signal Analyzer.

Advanced Monitoring During Test

Monitor health of your product during a vibration test with independent signal analysis measurements that execute during a vibration test.

100% Custom Reports

Generate your own report template in Microsoft Word using placeholder images and text. The 900 Series Controller fills in the placeholders with test parameters and results.

Acoustic + Vibration Measurements

Simultaneously acquire vibration and acoustic measurements from the same software and hardware platform.

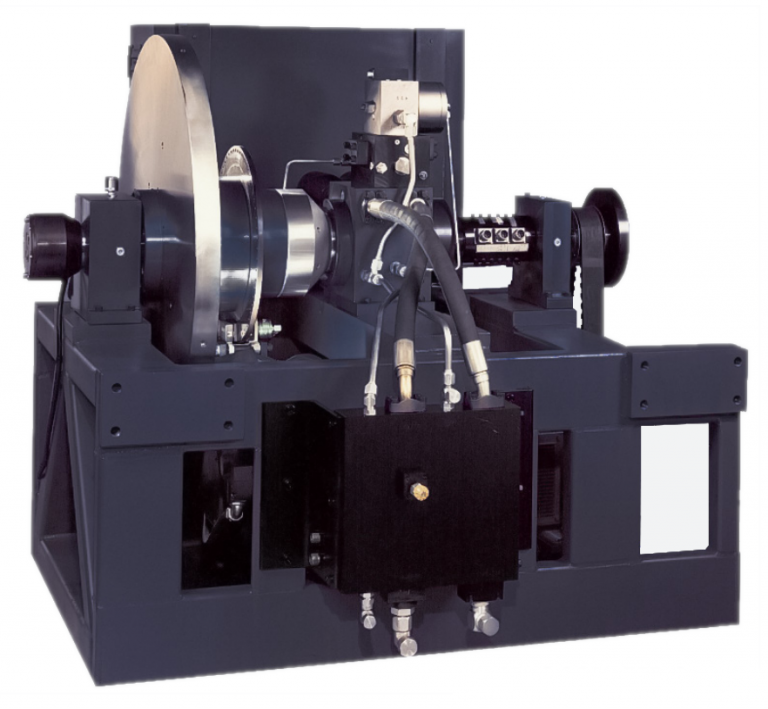

Powertrain Vibration Simulation

Data Physics controllers can be used along with the Team Corporation 901 Engine Simulator.

- Simulates rotary vibration seen in powertrains by simulating rotary motion (RPM) simultaneously with angular vibrations multiple, discrete frequencies

- Multiple angular vibration tones can be controlled simultaneously, simulating harmonic vibrations

- Rotary motion (RPM) can follow the angular vibration frequency, or remain constant to simulate transmissions’ excitation

- Complete, turnkey system provided by Data Physics and NVT Group partner company Team Corporation

Solutions for Electric Vehicle Battery Testing

Data Physics Shakers, Guided Head Expanders, and Controllers Provide a Safe, Feature Rich Solution for Testing Large EV Battery Assemblies

Multi-DoF Road Simulation

Record Road Vibrations in 6DoF

Use SignalCalc 900 to record multi-channel time domain vibration to capture 6DoF vibrations – or use the MIMO Analysis capability to reduce the time signals to a Spectral Density Matrix to use in a MIMO Random Vibration test.

Control 6DoF Road Vibration

Data Physics Controllers are the industry leaders in MIMO shaker control. Play back full 6DoF Vibration time histories on a 6DoF shaker such as the Team Cube (shown to the right) to replicate the exact vibration environment seen by your test article – or play back MIMO Random PSDs (Spectral Density Matrices), mechanical shock events, or more. See Multi Axis Controllers for more details.