Sensitive equipment vibration criteria testing

Monitor and Quantify Low-Amplitude Ground Vibrations to Ensure Sensitive Machinery Function Reliably

Precision Equipment

Precision equipment used in the semiconductor manufacturing, nanotechnology, electron beams, and optics, require low levels of ground vibration for desired results.

Vibrations from footfall, vehicle pass-by, construction, aircraft, local railroads, facilities, wind, or even air pressure can all induce vibrations in a building’s structure.

In these precision applications the smallest ground-borne vibrations may cause errors and be costly.

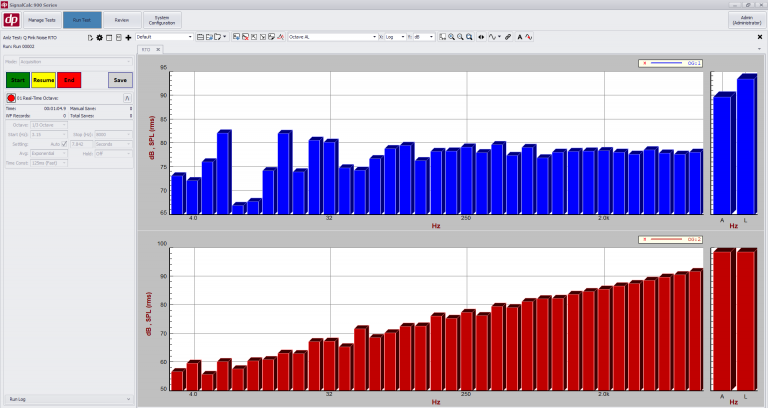

BBN and VC Curves

Measurements are compared to tolerance limits defined by standards including BBN curves, IEST VC curves, and ASHRAE curves.

- Import threshold curves in octave or narrowband

- Display curves in velocity, acceleration, or displacement

- Monitor vibrations continually or instantaneously

- Pass/Fail criterion with readout on displays

Octave Bands

The comparison measurements are often done in frequency spectra based third octave bands of velocity data.

- Easily acquire high-accuracy velocity data or acceleration data

- Convert acceleration to velocity

- Display the frequency data in corresponding band (1/3 octave) displays.

Choosing the Right Signal Analyzer

Such low level measurements require enough resolution to be able to accurately record low level signals. Proper sensor selection is also critical.

Additionally, using a Dynamic Signal Analyzer that has a high dynamic range is also critical to the measurement quality. With 140+ dB or better dynamic range, SignalCalc Dynamic Signal Analyzers are well suited for low level applications.